Automated Test Equipment / End of Line Tester (EOL) :

Automated Test Equipment / End of Line Tester :

Motor, Alternator Test System:

- Control and log data of alternator under test.

- Various tests like voltage regulation, temperature rise test etc can be carried out automatically

- Automatic inductive and resistive loading of the alternator

- Report generation

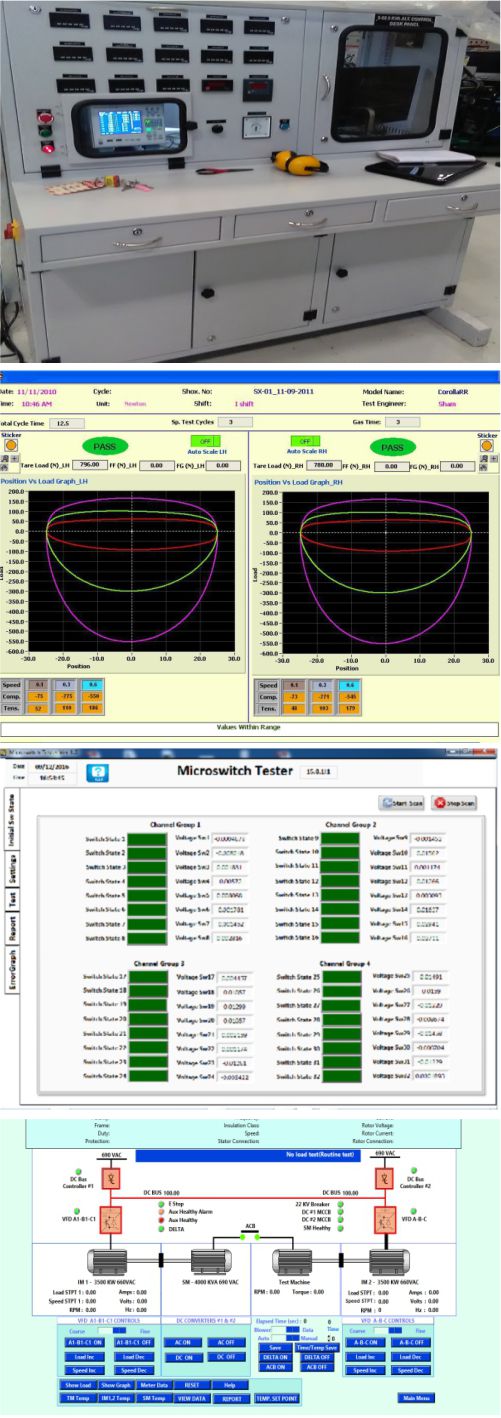

Shock Absorber Test System:

- Calculates compression and tension values of a shock absorber.

- Plots online graph

- Generates final result based on the tolerance band set by the user

Electrical Contactor Test Bench:

- 6 station test bench

- Test different characteristics of Electrical Contactor

- Test parameters are user configurable

ECU Tester

- No. of ECU's tested simultaneously.

- Improve existing and future control units

- Reduced time to detect and diagnose failure

Car Door Handle Tester :

- LabVIEW made the system adaptable for future software modification

- Continuous sampling , 20m sec sampling rate

- Reduced testing time by almost 50 percent

Gear Box Testing:

- Gear shifter lever will be operated with the help of motor.

- User needs to teach the path to follow gear sequence.

- Different parameters will be captured during this endurance test

Body Control Module :

- Ensuring Safety, testing and control of electrical load parameters.

- Maintaining Communication between integrated control unit through CAN or Ethernet n

- Improved productivity. Faster cycle time

Ultra High Speed Switch tester :

- 32 Voltage channnels at 6 micro seconds data logging

- Real time OK -Not OK Monitoring of all channels

- Reduced testing time increased efficiency

- High Scanning Rate as 6 Microseconds

Cluster Tester:

- Performance test, Endurance test for vehicle electronics

- CAN Communication Interface

- Provision for future expansion, store test data into a different database

Generator test system :

- 1.2 MWatt Generator is tested with back to back loading

- Futuristic design

- Analysed reports are generated in prescribed formats