Process Control :

High-Quality Process Control Instruments | PID Controller

In today’s dynamic industrial environment, precision, efficiency, and dependable control systems are crucial for seamless operations. At Theta Control, we focus on delivering state-of-the-art Process Control Instruments designed to streamline industrial processes and boost productivity. Serving diverse sectors such as manufacturing, energy, and other industries requiring advanced control solutions, we provide customized instruments to meet specific needs. Whether it’s a PID Temperature Controller or any other Process Control Instrument, our mission is to empower industries with innovative technologies that drive performance and reliability.

What is Process Control?

Process control refers to the techniques and tools used to monitor and adjust a process in real-time to maintain the desired output. Process control is crucial in industrial settings for maintaining consistency, improving quality, and ensuring safety. It allows industries to optimize production processes, reduce waste, and enhance energy efficiency. A robust process control system guarantees that a continuous industrial process operates smoothly, reliably, and at peak efficiency, with minimal variation. When implemented correctly, process control systems offer businesses numerous advantages, including improved operational performance and product quality.

Process Control Instruments

At Theta Control, we offer a range of Process Control Instruments that provide the precise measurements and control necessary for maintaining optimal conditions in industrial environments. These instruments are used to monitor and manage variables such as temperature, pressure, flow, and level within an industrial process. Utilizing advanced technology and software, these instruments enable industries to monitor and adjust process variables accurately.

Instrumentation and control in industrial applications involve tools such as temperature, pressure, flow, and level sensors, analyzers, and actuators. These tools work in unison with automated control systems to achieve optimal performance in manufacturing or production settings. PID controllers are among the most commonly used tools in process control, offering a reliable method to maintain stable and controlled system parameters.

PID Controllers and Their Functionality

A PID controller (Proportional, Integral, Derivative controller) is a type of control loop mechanism that uses feedback to regulate process variables such as temperature, pressure, and flow. The primary function of a PID Temperature Controller is to maintain a setpoint by adjusting the output in response to changes in the process variable. The controller calculates the error value—the difference between the desired setpoint and the actual process measurement—and applies corrections based on three terms:

Proportional (P): This term adjusts the output based on the current error value. A bigger mistake necessitates a bigger fix.

Integral (I): This term accounts for accumulated past errors, helping eliminate any residual steady-state error.

Derivative (D): By taking into account the error's rate of change, this term forecasts future errors.

Together, these three components help the PID controller deliver accurate, stable, and responsive control, making it an indispensable tool for industries requiring precise regulation of temperature and other process variables.

Different Types of Process Controllers

While PID controllers are highly effective in many industrial applications, other types of controllers also play a role in process control. The primary types of controllers include:

1. On-Off Controllers: This is the simplest form of temperature control. It operates by switching between two states: either on or off. When the temperature exceeds the setpoint, the controller turns the output off, and when it falls below the setpoint, the controller turns the output on. Though effective for some basic applications, on-off controllers tend to cause temperature fluctuations, making them less ideal for processes that require precision.

2. Proportional Controllers: Unlike on-off controllers, proportional controllers reduce the power delivered to the system as the temperature approaches the setpoint. This gradual adjustment prevents overshooting and maintains a more consistent temperature. The proportional controller is more advanced than the on-off controller, but it may still struggle with some degree of fluctuation in temperature.

3. PID Controllers: PID controllers combine the benefits of proportional control with integral and derivative actions to provide superior accuracy and stability in maintaining the setpoint. PID temperature controllers are used in applications where precise regulation is crucial, and they excel at minimizing overshoot and steady-state error. By adjusting the three parameters—proportional, integral, and derivative—PID controllers can adapt to varying conditions and ensure the process operates at an optimal level.

Features of PID Temperature Controllers

Modern digital PID controllers are designed with several key features that make them indispensable in industrial process control. Some of the notable features include:

High Precision and Accuracy:

Digital PID controllers offer precise control over temperature and other process variables, ensuring that the process runs at the desired setpoint with minimal deviation.

Programmable Settings: Many digital PID temperature controllers allow users to set different parameters for different time intervals, improving the flexibility of the control system.

User-Friendly Interface: Modern PID controllers come with intuitive interfaces, making it easy for operators to set and adjust control parameters without the need for extensive training.

Real-Time Monitoring: Advanced controllers provide real-time monitoring and feedback, allowing operators to quickly detect and respond to any deviations in the process.

Alarm and Notification Systems: Most PID temperature controllers are equipped with alarm systems that notify operators of any issues, such as temperature excursions or system failures, ensuring timely intervention.

Data Logging and Analysis: Many controllers feature data logging capabilities, enabling the collection of historical data for analysis and reporting. This is essential for process optimization and compliance with industry standards.

Applications of PID Controllers in Industry

PID controllers play a vital role in numerous industries, where precise control over process variables is necessary. Some of the primary applications of PID controllers include:

1. Temperature Control in Furnaces and Ovens: PID temperature controllers are commonly used in industries such as metallurgy and manufacturing, where precise control of furnace temperatures is crucial. Maintaining a consistent temperature ensures optimal material properties and reduces waste.

2. Flow and Pressure Regulation: In industries such as oil and gas, water treatment, and chemical processing, PID controllers regulate the flow of liquids and gases, ensuring safe and efficient operations.

3. Humidity Control: In applications where humidity is a critical parameter, such as in food production, pharmaceuticals, and electronics manufacturing, PID controllers maintain stable humidity levels to ensure product quality.

4. Power Conversion: PID controllers are also used in power conversion systems, such as in renewable energy applications, to track maximum power output and maintain system stability.

PID Temperature Controllers in Pune

At Theta Control, we are proud to offer PID Temperature Controllers and other Process Control Instruments in Pune, catering to industries in need of advanced instrumentation and control solutions. Our products are designed to meet the highest standards of quality and reliability, ensuring that industries in Pune and beyond can operate with confidence and efficiency.

Whether you're looking for PID controllers for temperature control or other advanced process control instruments, we offer a range of products tailored to suit your specific needs. Our team is committed to providing exceptional service, technical support, and expertise to help you implement the ideal control systems for your operations.

Our atest TH.PID 1 series with many innovations

- Heater break detection

- Profile Controller

- Multiple event inputs

- Remote setpoint

- High Accuracy 18 Bit A-D-C Input and 15 Bit-AGropur D-A-C Output

- True Universal Inputs of Thermocouple, RTD, MA, V

- Fuzzy+PID Control

- Possibility of both RS-485 and Analog Transmission

- Auto Tuning

- 2 Programs Each With 8 Segments of Ramp & Son

- Up to 6 Event Inputs

- CT inputs For Heater-Break Detection

- High Sampling Rate of 200msec

- Bidirectional Menu Navigation

- Total 9 profiles with 16, 32, and 64 segments at most

- Each segment is to be configured as a ramp or dwell (soak)

- The fast sample rate of 200 msec

- Up to three relays are configurable for event output

- Analog retransmission

- Optional RS-485 or RS-232 communications

- DAQ software is available and can be customized

- It supports many PLCs like (ABB, GE Fanuc, Siemens, etc.)

- Supports various protocols like Modbus, Ethernet, CAN open, Profibus, etc

- Data logging, bar graphs, trends, and alarms.

- Animation: display/hide, flash, color change.

- FDA 21 CFR - Part 11 Compliance

- Many types of IO modules available

- RS-485 with Modbus RTU protocol

- Can be used as external channels for PR series Paperless Recorders

- Add on 10 to existing PLC, HMI & SCADA systems

- Cost effective Remote IO solution

- Data Acquisition software available and can be customized

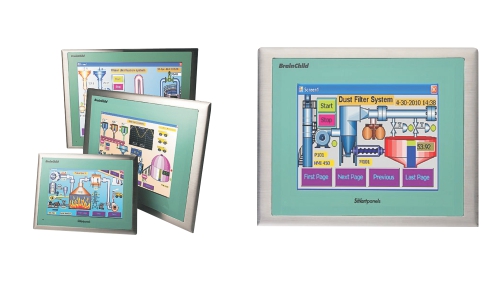

- All-in-one device including functions of PLC, HMI, and I/O modules

- 10.4-inch TFT LCD True Colour display

- Horizontal / Vertical installation

- Communication: RS232, RS422/485, Ethernet, CAN, USB, VGA, HDMI, Audio

- 32 input and 32 output points provided

- Motion control and high-speed counting function included

- Auto-tuning /Self-tuning and Fuzzy Logic

- Inputs: T/C, RTD, mA, V DC, Analog input for Remote Set Point

- Outputs : Relay/Pulse/mA/V DC, Analog Retransmission Output

- Optional: RS-485/RS-232 Interface

- Event input for changing function, set point

- DAQ software is available and can be customized

MCT Series - Multi-Loop Controller

The MCT system combines multiple control and monitoring elements in a single device. The 4.3” color touch screen allows users to select PC type menu or smart device slide-nav icon navigation to match familiar personal preferences for operation. Secure email (SSL/TLS), SMS, FTP, FileWeb and DataWeb/Cloud protocols allow the MCT to interface and backup data to LAN/WAN systems and databases, eliminating the need for additional data acquisition equipment. Math/Logic/Timer functions are included as standard to reduce additional system components.

- Up to 3 PID loops - 1 may be FM Limit

- Paperless recorder/data logger

- Trend viewer/data viewer

- File transfer/backup via LAN/ WAN/Cloud. Configure via USB memory stick or cloud.

- Math/Logic/Timers

- Up to 8 monitoring points

- Email on alarm

- Remote access

- NEMA 4X / IP 65

IP65 PID Controllers

TH-PID-146 PID controller is specially designed for temperature control. It's PID algorithm makes control more stable. This device supports popular TC and RTD inputs. It is also equipped with a dual-color LCD display, IP65 protection and user-friendly operations at a competitive price, to fulfill various temperature control demands.

- High-brightness LCD display

- Low depth - 65mm

- Parameter lockout protection

- High-accuracy 18-bit A-D input and 15-bit D-A output

- 200ms sampling rate

- Input signals: TC (J, K, T, R, S), RTD (PT100)

- Auto-tuning

- RS485 communication (optional)

- IP65 (Optional)