Recorders :

Paperless Recorders: Revolutionizing Data Management for Industrial Efficiency

In today's competitive industrial landscape, seamless data acquisition, real-time monitoring, and efficient storage are essential for informed decision-making and operational success. Theta Controls, a leading Paperless Chart Recorder manufacturer in Pune, offers advanced Paperless Temperature Recorders, Hybrid Data Loggers, and PID Process Controllers to empower industries in India with robust, efficient, and paperless solutions.

Why Choose Paperless Recorders?

Traditional paper-based chart recorders are gradually being replaced by advanced paperless chart recorders due to their numerous benefits. These digital devices eliminate the need for physical charts, reducing operational costs and human error while improving accuracy. Paperless recorders provide clear, real-time data visualization, analysis, and storage in a digital format, allowing easy access and decision-making capabilities.

Theta Controls’ Paperless Temperature Recorder solutions are designed to meet the needs of industries such as pharmaceuticals, food processing, oil & gas, chemicals, and manufacturing. With a user-friendly interface and advanced functionality, these devices are transforming how industries monitor, track, and analyze process data.

Hybrid Data Logger: Versatility in Data Acquisition

A Hybrid Data Logger combines the best of both worlds, offering analog and digital data collection capabilities in one device. This versatility makes it ideal for industries that require precise monitoring of various parameters such as temperature, pressure, and humidity.

Key Features of Hybrid Data Loggers:

- Multiple Input Options: Supports both analog and digital inputs for seamless data collection from different sources.

- Large Storage Capacity: Offers extensive data storage capabilities, making it ideal for long-term monitoring.

- Real-time Data Logging: Collects and logs data continuously, ensuring no data loss during operation.

- Customizable: This can be tailored to meet the specific needs of any industrial application, ensuring flexibility and scalability.

Theta Controls' Hybrid Data Loggers are perfect for industries that require comprehensive data collection systems capable of handling diverse input types, ensuring accurate data for better decision-making.

PID Process Control for Paperless Recorders

Integrating PID (Proportional-Integral-Derivative) Process Control with Paperless Recorders enhances system efficiency by continuously regulating temperature, pressure, or other variables within preset ranges. This dynamic control system ensures your industrial processes are optimized for stability, safety, and consistency.

Key Features of PID Process Control in Paperless Recorders:

- Precision Control: PID control maintains constant control over industrial processes, minimizing fluctuations in key parameters.

- Real-Time Monitoring: Ensures that process parameters are continuously monitored and adjusted in real-time for optimal performance.

- User-Configurable Settings: Easily customizable PID settings to match the unique needs of various industries.

- Improved Product Quality: By maintaining the required parameters with precision, PID control ensures consistent product quality and process output.

By incorporating PID Process Control with Paperless Chart Recorders, industries can benefit from precise, automated control over critical processes, enhancing overall productivity and minimizing downtime.

Advantages of Paperless Chart Recorders

- Cost-Effective: Eliminates the need for paper, ink, and manual documentation, lowering operating costs.

- Enhanced Accuracy: Provides highly accurate readings and eliminates human errors associated with traditional methods.

- Efficient Data Storage and Retrieval: Data is digitally stored for easy access, retrieval, and analysis at any time.

- Remote Monitoring: Many systems offer remote monitoring capabilities, enabling users to track real-time data from anywhere.

Applications of Paperless Recorders

- Manufacturing: Optimize manufacturing processes by accurately tracking temperature and pressure, ensuring product consistency.

- Pharmaceuticals: Essential for maintaining stringent temperature controls and compliance with industry regulations.

- Food Processing: Monitor and control cooking, pasteurization, and refrigeration processes to maintain food safety standards.

- Oil & Gas and Chemicals: Ensure that industrial processes remain within safe parameters to prevent accidents and maximize efficiency.

Key Features of Theta Controls’ Paperless Recorders

- Advanced Data Visualization: Provides real-time graphing and reporting for easy understanding and analysis of data.

- Wide Input Range: Supports various input types, including thermocouples, RTDs, and analog signals, ensuring compatibility with a wide range of industrial processes.

- User-Friendly Interface: Simple, intuitive controls make setup and monitoring effortless, even for operators without extensive technical knowledge.

- Scalability: Can be customized and scaled to meet the needs of any industrial setup, from small-scale operations to large, complex systems.

- Compliance and Certification: Meets industry standards, ensuring that your operations comply with regulatory requirements.

Theta Controls: Your Trusted Paperless Recorder Supplier

As a premier Paperless Chart Recorder manufacturer in India, Theta Controls is committed to providing high-quality, reliable, and cost-effective solutions for industrial automation. Our Paperless Recorders, Hybrid Data Loggers, and PID Process Controllers are designed to streamline your data management, enhance operational efficiency, and improve overall process control.

Whether you're looking for a Paperless Chart Recorder in Pune or seeking to optimize your industrial operations with advanced data logging and process control solutions, Theta Controls is your trusted partner for innovation and quality in India.

Are you ready to embrace the future of data acquisition and management? Contact Theta Control today to explore how our Paperless Chart Recorder solutions can streamline your operations, enhance efficiency, and contribute to the overall success of your industrial endeavors in Pune.

- Error-free and user-friendly Automation Solutions

- Customized solutions for meeting all requirements

Manufacturing businesses are spending more money on industrial automation technology and industrial control systems to boost system efficiency and reliability while eliminating production inefficiencies. With the widespread use of automation solutions in the manufacturing, oil & gas, chemicals & materials, and pharmaceutical industries, the market for industrial automation is expanding quickly. Companies can significantly reduce operating and labor expenses by implementing automation components and enterprise control solutions.

Using control systems, computers or robots, and information technology for managing various processes and machinery in an industry to replace humans comes under industrial automation.

- Advantages of Industrial Automation

- Improves precision and flexibility

- Lower direct labor costs and expenses

- Boosts productivity

- Improves process or product consistency

- Delivers high-quality products

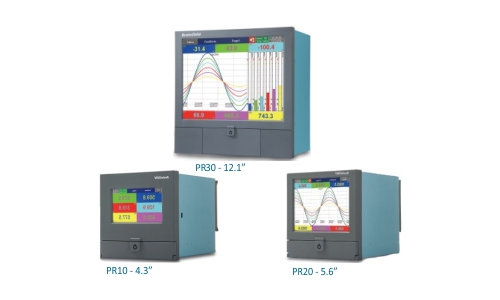

Paperless data collection and analysis are made possible with paperless recorders that offer a secure, reliable, and affordable solution. Paperless recorders from the PR series are available with amazing features and specifications and can have built-in PID controls.

Features

- Fast logging speed: 100msec sec

- 2 USB, web server, email, and many more features

- Supports pulse input, all T/C, RTDs, and Linear Inputs

- Math Channels available

- 48/24/6 input channels and max up to 96/48/24 external channels

- IP65 high-resolution touch screen display

- Communication Standard Ethernet - Optional RS-232/RS-485/RS-422

- DAQ software is available and can be customized

- Can have 1/2 channel PID Controls built-in (with Profile controller)

- FDA 21 CFR - Part 11 Compliance

Numerous display features, including a trend display, a bar graph display, and a numerical display with a touch pen, characters and, images can be drawn on the screen and saved as data where Ethernet and upper / lower communication are optional.

Benefits

- View real-time display of data in various formats

- Digitally transfer and store all results

- The built-in display allows users to review measured data in real-time quickly

- Ease of use due to info-graphics and touchscreen displays

- Batch recording or continuous data recording is possible

For data recording, storage, and reading-in of settings, hybrid recorders contain an integrated SD card port (cards available separately). Additionally, these recorders feature an LCD digital display for easy monitoring of the measured values. THETA Control is the leading Paperless Temperature Recorder Supplier in India.

Features

- Combined functions of paper recorder and paperless recorder

- Enables to print the saved data of inner memory when running out of recording paper(data logger function)

- Recorder, 50/100mm, 12 Channel, 12 Alarm output, RS485 Ethernet/USB, 100 to 240VAC

- High-speeded sampling of 25 ms, a high-speed record of 240 mm/H functions

- Space-saving for installation with compact design (rear length: 168 mm)

- Supports total 27 kinds of input types

- Enables order of several types of input cards (weight, voltage, current frequency, potential meter, etc.)

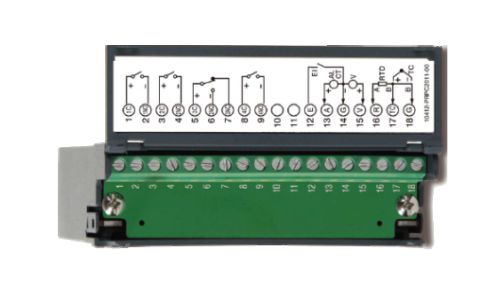

To regulate and record the data, most furnace applications often require a separate Controller and Recorder. Ramp & Dwell controls are required for some furnace applications. Using the new process control Card PC201, the new generation Paperless Recorder offers PID Control, Ramp & Dwell Control and Recording in a single device. For furnace applications, this single-loop controller is used. This reduces the cost, space, and wiring required to use the controller and recorder independently.

Fuzzy Logic and PID microprocessor technologies regulate the Process Control Card. PID microprocessor-based technology and Fuzzy Logic allow a process to achieve a predetermined set point in the least amount of time, with the least overshoot during power-up or external load disruption. The module is simply connected to the paperless recorder's back-side IO slots. The touchscreen menus and navigation allow for a simple configuration of several control and input parameters. The device's Configuration Menu or the PC-based Configuration Software can be used to configure this Process Control Card.

Features

- PID Controller, Ramp & Dwell Controller, and Recorder 3 in one Device

- 18-bit Universal input A-D for PID Control

- Fuzzy + PID microprocessor-based control

- 50 Profiles,1000 Segments in Total

- Auto-tuning and Self Tuning function

- " Soft-start " Ramp and Dwell timer

- Universal inputs( Thermocouple, RTD, mA, VDC )

- Analog input for remote set point and CT

- Event input for changing function & set point